范文一:导线安全载流量

塑 料 绝 缘 线(35?) 标称截穿管敷设 护套线 明线敷设 面积 二根 四根 二芯 三及四芯

铜 铝 铜 铝 铜 铝 铜 铝 铜 铝 m?

0.5 8 7.5 5

0.7 12 10 8 0.8 15 11.5 10 1 18 15 13 14 11 1.5 22 17 18 13 15 11 18 14 12 10 2 26 20 20 15 16 12 20 16 14 12 2.5 30 23 26 20 23 17 22 19 19 15 4 40 30 38 29 30 23 33 25 25 20 6 50 39 44 34 37 28 41 31 31 24 8 63 48 56 43 43 34 51 39 40 30 10 75 55 68 51 49 37 63 48 48 37 16 100 75 80 61 64 49 20 110 85 90 70 74 56 25 130 100 100 80 85 65 35 160 125 125 96 105 75 50 200 155 163 125 120 89 70 255 200 202 156 161 125 95 310 240 243 187 197 152 注:1,线芯最高的工作温度:塑料绝缘线为70?,橡皮绝缘线为65?。 2,电线周围环境温度为35?。当实际空气温度高于35?的地方,导线安全载流量应按校正系数表乘以校正系数。

校正系数表

周围空气温度 35? 40? 45? 50? 55?

塑料绝缘线 1.00 0.93 0.85 0.76 0.66 校正

系数 橡皮绝缘线 1.00 0.91 0.82 0.71 0.58

橡 皮 绝 缘 线(35?)

穿管敷设 护套线 标称截面积 明线敷设 二根 四根 二根 四根 m? 铜 铝 铜 铝 铜 铝 铜 铝 铜 铝 0.5 7 4.5 0.7 9 7.5 1 17 14 12 12 10 1.5 20 15 16 12 14 10 15 12 11 8 2 24 18 18 14 15 11 17 15 12 10 2.5 28 21 24 18 21 16 19 16 16 13 4 37 28 35 26 27 21 28 21 21 17 6 46 36 40 31 34 26 35 26 26 21 8 58 44 50 40 40 31 44 33 34 26 10 69 51 63 47 45 34 54 41 41 32 16 92 69 74 56 59 45 20 100 78 83 65 68 52 25 120 92 92 74 78 60 35 148 115 115 88 97 70

50 185 143 150 115 110 82

70 230 185 186 144 149 115 95 290 225 220 170 180 140

120 355 270 260 200 210 165

150 400 310 290 230 240 188

185 475 370

240 580 445 300 670 520 400 820 630 500 950 740

空气温度不等于25?时载流量的温度校正系数

电缆芯最高空 气 温 度

允许温度? -5? 0? 5? 10? 15? 20? 25? 30? 3?5 40? 45? 80 1.24 1.2 1.17 1.13 1.09 1.04 1.0 0.95 0.90 0.85 0.798 65 1.32 1.28 1.23 1.17 1.12 1.06 1.0 0.94 0.86 0.8 0.707 60 1.37 1.31 1.27 1.21 1.15 1.07 1.0 0.93 0.85 0.70 0.655 50 1.48 1.41 1.33 1.26 1.18 1.09 1.0 0.89 0.77 0.63 0.447

范文二:BV铜导线载流量

BV 铜导线载流量

导体工作温度 70°C 环境温度 (°C) 导线排列 30 35 O-S-O-S-O 9~1 导线根数 1 2~4 5~8 2 标称截面 (mm 2) 1.5 2.5 4 6 10 16 25 35 50 70 95 120 150 185 240 明敷载流量(A) 23 31 41 53 74 99 132 161 201 259 316 374 426 495 592 22 29 39 50 69 93 124 151 189 243 297 351 400 464 556 20 27 36 46 64 86 115 140 175 225 275 325 370 430 515 13 17 24 31 44 60 83 103 127 165 207 245 288 335 396 9 13 18 23 33 45 62 77 95 123 155 184 216 251 297 8 11 15 19 28 38 52 64 79 103 129 153 180 209 247 7 10 13 17 25 34 47 58 71 92 116 138 162 188 222 上 12 以 2~4 40 30

0.45/0.75 kV

35

40

9~1 5~8 2

12 2~4 以上 5~8

9~1 2

12 以 上

导线穿管敷设载流量(A) 12 16 22 29 41 57 77 96 117 152 192 226 265 309 366 9 12 17 21 31 42 57 72 88 114 144 170 199 232 275 7 10 14 18 26 35 48 60 73 95 120 141 166 193 229 6 9 12 16 23 32 43 54 66 85 108 127 149 174 26 11 15 21 20 38 52 70 88 108 140 176 208 244 284 336 8 11 15 20 29 39 53 66 81 105 132 156 183 213 252 7 9 13 16 24 32 44 55 67 87 110 130 152 177 210 6 8 11 15 21 29 39 49 60 78 99 117 137 159 189

注:明敷载流量值系根据 S>2De(De-电线外径)计算

范文三:导线载流量计算

导线载流量计算

Selection of wire diameter

The current carrying capacity of the wire is related to the cross section of the conductor, but also to the material, type, laying method and environmental temperature of the conductor. There are many factors affecting the calculation and the calculation is more complicated. The ampacity of various wires can usually be found in the manual. But the use of formulas with some simple arithmetic, can be calculated directly, without look-up table.

1. formulas of aluminum core insulation wire section carrying capacity and multiple relationship

10, five, 100, two,

25, 35, four, three,.

70, 95, two and a half times.

Tube, temperature, eight or nine fold.

Add half bare.

Copper upgrade.

2. formulas for various section carrying capacity (ANN) is not directly pointed out, but with the section multiplied by a certain multiple representation. For this reason, the nominal sections (mm2) of our usual wires are arranged as follows:

1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70,, 95, 120, 150, and 185......

(1) pointed out that the first sentence rhymes aluminum core insulated wire carrying capacity (ANN), according to the times of calculation section. The formulas in Arabia digital said the conductor section (mm2), Chinese characters digital times. The formulas of section and multiple relationships arranged as follows:

1~1016, 2535, 5070, 95120 or more

.

Five times four times three times two times two times

Now more and more clearly the control formula, formula "10 under five" refers to the section below 10, carrying capacity is five times the value of cross section. "100 on two" (read hundreds of two) refers to the cross section of more than 100 of the carrying capacity is two times the value of the cross-section. A cross section of 25 and 35 is four times and three times the dividing line. This is the formula 25, 35, four realms "". And the cross section 70 and 95 is two point five times. From the above arrangement, it can be seen that in addition to 10 and over 100, the cross section of the middle wire is of the same kind in each of the two specifications.

For example, aluminum core insulation line, the ambient temperature is not greater than 25 degrees of temperature

calculation of the carrying capacity:

When the cross section is 6 mm2, the ampacity is 30;

When the cross section is 150 mm2, the ampacity is 300;

When the cross section is 70 mm2, the ampacity is 175;

It can also be seen from the above arrangement that the multiples decrease with the increase of the cross section, and the error is slightly larger at the junction of the multiples change. For example, section 25 and 35 is the boundary between the four and three times, four times the range of 25 genera, which according to the formula for the 100 count, but according to the manual for the 97 and 35; instead, according to the formula is 105, but the look-up table for the 117. However, this has little effect on the use. Of course, if a few chest, in the lead section, 25 do not make it full to 100, 35 is slightly more than 105. It is more accurate. Also, the location of the line 2.5 square mm five times in the beginning, in fact more than five times (maximum 20 above), but in order to reduce the power loss in the wire, usually are not so much to the current manual, only 12.

(2) three is behind the formulas for processing conditions change. "Through tube and temperature,

Eight or nine fold "means: if the laying (including groove plate, wire laying is a protective sleeve layer, exposed, after calculating the unknown), call twenty percent off; if the ambient temperature is above 25 degrees Celsius, then play the

ten percent off calculation, if both laying, the temperature more than 25 DEG C, call again ten percent off call twenty percent off, or by a simple calculation thirty percent off.

About the environmental temperature, according to the Regulations refers to the highest average on the hottest summer temperatures. In fact, the temperature is changing, and generally it doesn't affect the current carrying capacity of wires. Therefore, only a certain temperature workshop or more hot area more than 25 degrees before considering discount.

For example, the calculation of the download flow of an aluminum insulated wire under different conditions:

When the cross section is 10 mm in the tube, then the load flow is 10 x 5 x 0.8 40 one; if the temperature is loaded flow is 10 x 5 x 0.9 45 one; if the tube and high temperature wear, then load flow is 10 x 5 x 0.7 one 35.

Cable type, type, name and parameter

First, the commonly used cable

Model name scope of application

YJV

YJLV

ZR-YJV

ZR-YJLV flame retardant and non flame retardant or aluminum core XLPE insulated and PVC sheathed power cables, suitable for indoor and outdoor laying. The utility model can be subjected to certain laying and traction, but can not bear the occasion of mechanical external force. Single core cables are not allowed to be laid in magnetic ducts.

YJV22

YJLV22

ZR-YJV22

ZR-YJV22 flame retardant and non flame retardant copper core or aluminum core XLPE insulated and PVC sheathed steel tape armored power cable, suitable for laying underground, can bear mechanical external force, but can not withstand large tensile force.

YJV32

YJLV32

ZR-YJV32

ZR-YJV32 flame retardant and non barrier copper core or aluminum core XLPE insulated and PVC sheathed steel wire armored power cable, suitable for use in water or high drop area, can bear mechanical external force and considerable tensile force.

Can also produce PVC sheath YJY, YJLY products

Production range

Rated core voltage

3.6/6, 6/6,6/10, 8.7/10,8.7/15, 12/20, 21/35, 26/35,26/45

Nominal cross section of conductor wire mm2

YJV

YJLV

ZR-YJV

ZR-YJLV 1, 25~630, 25~630, 25~630, 35~630, 50~630, 50~630

3, 25~500, 25~500, 25~500, 35~500, 50~400, 50~400

YJV22

YJLV22

ZR-YJV22

ZR-YJV22 3, 25~500, 25~500, 25~500, 35~500, 50~240, 50~240

YJV32

YJLV32

ZR-YJV32

ZR-YJV32 1, 25~500, 25~500, 25~500, 35~500, 50~500, 50~500

3, 25~300, 25~300, 25~300, 35~300

Product standards, specifications and cross sections not included in the table may also be produced according to user requirements

Two PVC insulated control cables (basic type: KVV)

The cable is suitable for AC rated voltage 550V or DC voltage 1000V and below

The cable conductor core allows a longer operating temperature of not more than 70 degrees centigrade

When laying, the cable temperature is not less than 0 degrees centigrade

The bending radius of the cable shall be no less than 10 times of the cable diameter

Product standard: GB9330.1.2-90 and reference International Electrotechnical Commission IEC 227, IEC 332.3, IEC 331

Insulating sheath; material property; project insulation jacket

The tensile strength of N/mm2 = 12.5 = 12.5

More than 150 more than 150 elongation%

The temperature is 80 + 280 + 2

Time HR 168168

The tensile strength of N/mm2 = 12.5 = 12.5

Hot air aging properties K1% 80-120 80-120

More than 150 more than 150 elongation%

K2% 80-120 80-120

The weight loss of mg/cm2 is less than or equal to 2 or 2

The temperature is 150 + 2150 + 2

Thermal shock performance time HR 11

Performance requirements, no cracks, no cracks

The temperature is 80 + 280 + 2

Thermal deformation performance time HR 44

Performance requirements 5050

Temperature 15 15 + 2 + 2

Cold bending performance time HR 1616

Performance requirements, no cracks, no cracks

Temperature 15 15 + 2 + 2

Cold shock performance time HR 1616

Performance requirements, no cracks, no cracks

Insulation dielectric constant (K value) 70 C = 0.0037

The cable structure is shielded

1. copper wire

2. PVC insulation

3. pack belt

4. tinned copper wire braid

5. PVC sheath

Three 、 XLPE insulated control cable

The cable is suitable for the wiring of the electric instrument in the distribution device under the fixed rated voltage 550V or the direct current voltage 1000V.

The conductor work temperature shall not exceed 90 centigrade for a long time.

In short circuit, the maximum temperature of conductor shall not exceed 250 DEG C, and the duration of short-circuit shall be 5 seconds.

When it is laid below 0 degrees, the cable must be heated in advance.

Product standard: GB9330.1.2 and reference International Electrotechnical Commission IEC 502, EC 332-3, IEC 331

Cable type, name and scope of use

Model name range of use

KYJV XLPE insulated PVC sheathed control cables are laid in indoor, cable trench and pipe fixed place

ZR-KYJV XLPE insulated PVC sheathed flame retardant control cables are installed in indoor, cable trench and pipe fixed flame retardant sites

NH-KYJV XLPE insulated PVC sheathed refractory control cables are installed in indoor, cable trench and pipe fixed fire place

KYJV22 XLPE insulated steel tape armored control cable is installed in indoor, cable trench, pipeline, directly buried, and can bear greater mechanical external force and other fixed place

ZR-KYJV22 XLPE insulated steel tape armored flame-retardant control cable is installed in indoor, cable trench, pipeline directly buried, and can withstand larger mechanical external force, flame retardant and other fixed place

NH-KYJV22 XLPE insulated steel tape armored refractory control cable is laid in indoor, cable ditch, pipeline, buried directly, and can bear larger mechanical external force, fire and other fixed place

KYJVP XLPE insulated copper wire shielding control cable is installed in indoor, cable trench and pipeline

ZR-KYJVP XLPE insulated copper wire shielding epoxy control cable is laid in indoor, cable trench, pipeline and other requirements of the flame retardant fixed place

NH-KYJVP XLPE insulated copper wire shielding refractory control cable, laying indoors, cable trench, pipeline and so on

Four 、 polyethylene insulated coaxial cable

Cables are suitable for closed-circuit television, common antenna television systems, sub branch lines and subscriber lines, and other electronic industrial devices.

Environmental temperature: - 25~+70, l

? relative temperature: 40+2 90%~95% L

Usage frequency: 5~960MHZ

Product standards: SJ/T10302 1,2,3,4 - 92

Type and name of cable

Model name

SYKV - 75 - 5

SYKV - 75 - 7

SYKV - 75 - 9

SYKV - 75 - 12 coaxial coaxial cable for vertical hole ethylene

insulated and PVC sheathed cable distribution systems

Basic structure of cable

Model SYKV - 75 - 5

Mm SYKV - 75 - 7

Mm SYKV - 75 - 9

Mm SYKV - 75 - 12

Mm

The inner conductor diameter is 1, 1.6, 2, 2.6

Sheath outer diameter 7.2, 10.3, 12.2, 15

Electrical performance

Project test conditions unit SYKV 75 - 5 SYKV 75 - 7 SYKV 75 - 9 SYKV 75 - 12

50HZ 1min voltage test KV = 1.6 = 1.6 = 1.6 = 1.6

The insulation resistance of 500V DC M Omega.Km = 5000 = 5000 = 5000 = 5000

Characteristic impedance 200MHZ = 72 = 78 = 72.5 = 77.5 = 72.5 = 77.5 = 72.5 = 77.5

The attenuation constant 50HMZ dB/100m = 5.3 = 3.4 = 2.8 = 2.4

200MHZ dB/100m = 10.8 = 7.1 = 5.7 = 4.6

800MHZ dB/100m = 22.9 = 15.2 = 12.5 = 10

The return loss VHF dB = 20 = 20 = 20 = 20

VHF dB = 18 = 18 = 13 = 13

Five PVC insulated cables and wires

Model name voltage rating V specification

BV copper core PVC insulated wire 300/500 1 core 0.75~1mm2

BLV aluminium core PVC insulated wire 450/750 1 core 2.5~400mm2

BVR copper core PVC insulated flexible wire 450/700 1 core 2.5~70mm2

BVV copper core PVC insulated and sheathed round wire 300/500 1 core 0.75~10mm2

BLVV aluminium core PVC insulated and sheathed round wire 300/500 1 core 2.5~10mm2

BVVB copper core PVC insulated and sheathed flat cable 300/500 2-3 core 0.75~10mm2

BLVVB aluminium core PVC insulated and sheathed flat cable 300/500 2-3 core 2.5~10mm2

RVS copper core PVC insulated twisted connection flexible wire 300/300 2 core 0.5~0.75mm2

AV copper core PVC insulated installation wire 300/300 1 core 0.08~0.4mm2

AVR copper core PVC insulated installation flexible wire 300/300 1 core 0.08~0.4mm2

AVRB copper core PVC insulated flat mounting flexible wire 300/300 2 core 0.12~0.4mm2

AVRS copper core PVC insulated winding type flexible wire

300/300 2 core 0.12~0.4mm2

AVVR copper core PVC insulated and sheathed flexible cable 300/300 2-2 core 0.08~0.4mm2

AV - 90 copper core heat resistant 90 degree PVC insulated installation wire 300/300 1 core 0.08~0.4mm2

AVR - 90 copper core heat resistant 90 degree PVC insulated installation flexible wire 300/300 1 core 0.08~0.4mm2

AVP copper core PVC insulated installation shielded wire 300/300 1 core 0.08~0.4mm2

RVP copper core PVC insulated shielded flexible wire 300/300 1 core 0.08~2.5mm2

RVVP copper core PVC insulated screened PVC sheathed 300/300 1-24 core 0.08~0.4mm2

RVVP1 copper conductor PVC insulated wrapped PVC sheathed flexible cable 300/300 1-24 core 0.08~0.4mm2

RVP - 90 copper core heat resistant 90 degree PVC insulated shielded flexible wire 300/300 1 core 0.08~0.4mm2

AVP - 90 copper core heat resistant 90 degree PVC insulated installation shielded wire 300/300 1 core 0.08~0.4mm2

Six 、 computer cable

The cable is used for the connection of electric apparatus, instrument and computer in the configuration of AC rated voltage 500V and below or DC voltage 1000V and below. The wire core allowed working temperature is less than 70 DEG C, laying temperature not less than - C, bending radius of cable is 10 times of the cable diameter and above.

Cable type, name and main use

Model name, main use

DJYVP PE insulated copper wire strong shield computer cable fixed laying

DJYVPR polythene insulated copper wire shielded cable for mobile cable laying

The DJYP3P3 grouping and aggregate composite aluminum polyethylene insulation shielding computer cable laying

Fixed laying of DJYVP3 polyethylene insulated composite shielding computer cable

DJYVP2 polythene insulated copper tape shielding computer cable fixed laying

Note: divided by the production of LV outside, also can produce flame retardant computer cable, model: ZR - DJYVP, ZR - DJYVPR, ZR - DJYP3P3, ZR - DJYVP3 - ZR - DJYVP2

Product standard: refer to UK BS 5308-1987

Seven (A) flame retardant power cable

Model name range of use

GZR-VV

GZR-VLV PVC insulated and sheathed oxygen insulated flame retardant power cables are laid indoors, in tunnels and in ducts, and the cables are not subjected to pressure and mechanical external force

GZR-VV22

GZR-VLV22 PVC insulated steel tape armored PVC sheathed oxygen insulated high flame resistant cable for indoor, tunnel and buried soil, cable can bear pressure and other external force

GZR-VV32

GZR-VLV32 PVC insulated, fine steel wire armored, PVC sheathed oxygen insulated flame retardant power cable, laid in indoor, mine, water, cable can withstand considerable tension

GZR-VV42

GZR-VLV42 PVC insulated, thick steel wire armored, PVC sheathed, chlorine resistant, high layer flame retardant power cable, laying in vertical shafts, water and other vertical occasions, can withstand considerable axial tension

Rated voltage (0.6/1kv) of production range

Model number nominal cross section (mm2)

Cu Al

GZR-VV GZR-VLV 1 1.5-630 2.5-630

GZR-VV22 GZR-VLV22 6-630 10-630

GZR-VV32 GZR-VLV32 16-630 25-630

GZR-VV GZR-VL 2 1.5-185 1.5-185

GZR-VV22 GZR-VLV22 2.5-185 2.5-185

GZR-VV32 (42) GZR-VLV32 (42) 4-185 6-185

GZR-VV GZR-VLV 34-300 6-300

GZR-VV22 GZR-VLV22

GZR-VV32 (42) GZR-VLV32 (32)

GZR-VV GZR-VLV 3+1; 44-300, 6-300

GZR-VV32 (32, 42) GZR-VLV32 (32, 42)

GZR-VV GZR-VLV 5; 4+1; 3+2 4-300 6-300

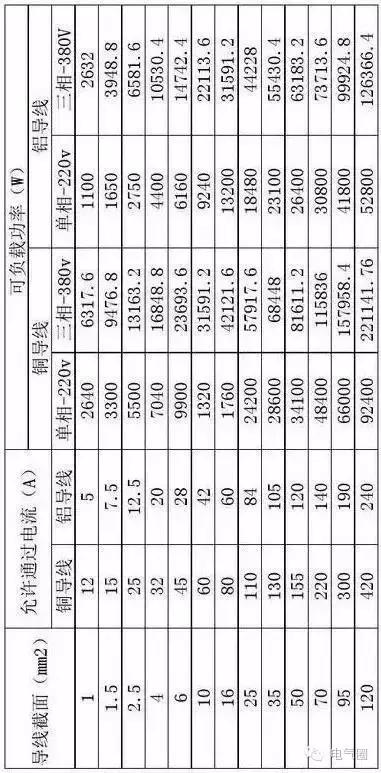

范文四:导线载流量计算

导线载流量计量参考

导线截面积与载流量的计算一般铜导线载流量导线的安全载流量是根据所允许的线芯最高温度、冷却条件、敷设条件来确定的。

一、一般铜导线的安全载流量为 5~8A/mm2铝导线的安全载流量为 3~5A/mm2。如2.5 mm2 BVV 铜导线安全载流量的推荐值 2.5×8A/mm2=20A 4 mm2 BVV 铜导线安全载流量的推荐值 4×8A/mm2=32A

二、计算铜导线截面积利用铜导线的安全载流量的推荐值 5~8A/mm2 计算出所选取铜导线截面积 S 的上下范围 S==0.125 I ~0.2 Imm2 S铜导线截面积mm2 I负载电流A

三、功率计算一般负载也可以成为用电器如点灯、冰箱等等分为两种一种式电阻性负载一种是电感性负载。对于电阻性负载的计算公式P=UI 对于日光灯负载的计算公式P=UIcosф其中日光灯负载的功率因数cosф=0.5。不同电感性负载功率因数不同统一计算家庭用电器时可以将功率因数cosф取 0.8。也就是说如果一个家庭所有用电器加上总功率为 6000 瓦则最大电流是 I=P/Ucos ф=6000/220*0.8=34(A) 但是一般情况下家里的电器不可能同时使用所以加上一个公用系数公用系数一般 0.5。所以上面的计算应该改写成 I=P*公用系数/Ucosф=6000*0.5/220*0.8=17(A) 也就是说这个家庭总的电流值为 17A。则总闸空气开关不能使用 16A 应该用大于 17A 的。

估算口诀:

二点五下乘以九,往上减一顺号走。

三十五乘三点五,双双成组减点五。

条件有变加折算,高温九折铜升级。

穿管根数二三四,八七六折满载流。

说明:(1)本节口诀对各种绝缘线(橡皮和塑料绝缘线)的载流量(安全电流) 不是直接指出而是 “截面乘上一定的倍数” 来表示通过心算而得。由表 5 3 可以看出倍数随截面的增大而减小。“二点五下乘以九往上减一顺号走”说的是 25mm’及以下的各种截面铝芯绝缘线其载流量约为截面数的 9 倍。如 25mm’导线载流量为 25×9225(A)。从 4mm’及以上导线的载流量和截面数的倍数关系是顺着线号往上排倍数逐次减 l即 4×8、6×7、10 ×6、16×5、25×4。“三十五乘三点五双双成组减点五”说的是 35mm”的导线载流量为截面数的 35 倍即 35×351225(A)。从 50mm’及以上的导线其载流量与截面数之间的倍数关系变为两个两个线号成一组倍数依次减 05。即 50、70mm’导线的载流量为截面数的 3 倍 95、120mm”导线载流量是其截面积数的 25 倍依次类推。“条件有变加折算高温九折铜升级”。上述口诀是铝芯绝缘线、明敷在环境温度 25℃的条件下而定的。若铝芯绝缘线明敷在环境温度长期高于 25℃的地区导线载流量可按上述口诀计算方法算出然后再打九折即可当使用的不是铝线而

是铜芯绝缘线它的载流量要比同规格铝线略大一些可按上述口诀方法算出比铝线加大一个线号的载流量。如 16mm’铜线的载流量可按 25mm2 铝线计算塑料电现电缆要适应各种不同需要就应具有广泛的优异而稳定的使用性能。塑料电线电缆的使用性能和寿命决定于产品结构的先进性、塑料选用的合理性以及工艺的完善性。从塑料电现电缆技术的发展来看合理而正确的使用材料是关键的因素。为了制造性能优异而稳定的塑料电线电缆在导电线芯和半成品缆芯满足规定的技术要求的前提下主要是对绝缘和护套用塑料提出了较高的要求。绝缘塑料的基本要求是具有优异的电绝缘性能同时根据产品用途和使用条件分别提出对机械性能、耐高温性、物理化学性能及工艺性能的要求。对护套塑料的基本要求是耐受各种环境因素作用的老化性能在满足这个条件下分别提出一些特殊要求和辅助要求。第一节塑料塑料是高分子合成材料中凡是性能上具有可塑性变化的材料的总称。塑料可分为热塑性塑料和热固性塑料两大类电线电缆制造中所用的塑料都是热塑性塑料。电线电缆常用的热塑性塑料有聚氯乙烯、聚乙烯、交联聚乙烯、泡沫聚乙烯、氟塑料、聚酰胺、聚丙烯和聚酯塑料等。塑料是以合成树脂为基本成份再添加各种配合剂经捏合、切粒等工艺而塑制成一定形状的材料。为了满足加工、贮存和使用的要求合成树脂内一般都要添加各种配合剂根据添加配合剂所起的作用不同塑料的添加剂大致有以下几种防老剂它包括抗氧剂、稳定剂、紫外线吸收剂、光屏蔽剂等这几种材料在塑料中所起的作用不同但又相互联系同一种材料可起几种作用所以统称为防老剂。增塑剂交联剂润滑剂填充剂着色剂发泡剂防霉剂驱避剂阻燃剂耐电压稳定剂抑烟剂等。各种塑料既具有塑料共有的特性又具有各不相同的各自独具的某些特性。各种塑料共有的特性有比重小、机械性能较高、电绝缘性能优异并且化学稳定性好、耐水、耐油、加工成型方便原料来源丰富。为了适应日益增长的电线电缆技术发展的需要塑料将不断改进配方和性能提高其耐热性和电压等级提高材料的耐寒、耐大气老化性能、耐火阻燃性能延长电线电缆使用寿命同时还将不断开发新型塑料并合理用于电线电缆上。一、塑料基本性能的含义塑料基本性能的含义 1. 体积电阻系数塑料在电场的作用下有泄漏电流通过泄漏电流通过塑料时的阻力称为体积电阻。电流通过每 1cm3 塑料的电阻即为体积电阻系数ρv单位为欧姆米单位符号为 .m。体积电阻系数越高绝缘性能越好 2. 击穿场强当塑料上施加的电压达到某一极限时塑料丧失绝缘性能被击穿击穿瞬间所施加的电压值称为塑料的击穿电压击穿电压与塑料厚度之比称为击穿场强 E 单位符号为 kV/mm。 3. 介电常数它是表示塑料极性大小的指标。介电常数 ε 越小塑料在电场作用下的极化强度越小其介质损耗也越小。 4.介质损耗角正切在交变电场作用下塑料中所消耗的级量称为介质损耗。它常以介质损耗角的正切值tgδ来表示。介质损耗角正切tgδ越小说明介质损耗也越小塑料的电绝缘性能越好。在高频、高压下使用时要求塑料的tgδ值不大于千分之几或万分之几低压和一般的绝缘时塑料的tgδ值则不大于百分之几。 5. 耐电晕性在高电压情况下由于绝缘表面放电而引起电晕当其袭击绝缘体时因离子撞击、电子袭击、臭氧袭击和局部热的作用导致高聚物裂解使其电绝缘性能和物理机械性能产生恶化。塑料抵抗电晕作用而保持其使用性能的能力称为耐电晕性。 6.抗拉强度和延伸率在材料拉力试验机上对塑料试样施加静态拉伸载荷并以一定速度拉伸直至试样断裂。此时试样单位截面上所承受的拉力称为该塑料的抗拉强度。试样拉断时长度增加的百分比称为该塑料的延伸率。

7. 密度在一定温度下通常指 20oC单位体积塑料试样的质量称为塑料的密度。 8. 耐热变形性塑料在受热条件下仍能保持良好的物理机械性能的最高温度即为该塑料的耐热变形性能。

通常以塑料在等速升温时在一定负荷下使其变形达到规定值时的温度来表示。 9. 熔融指数在一定温度荷压力下熔融树脂在 10 分钟内从一定孔穴中被压出的克数称为熔融指数以 MI 表示单位为 g/min。10.耐寒性在低温下塑料仍能保持一定的物理机械性能的能力称为塑料的耐寒性。它常用以下的耐寒温度来表示。 1低温脆化温度即为塑料在低温下受特定的冲击负荷时50 的试样出现损坏时的温度。 2低温对折温度即为塑料试样在弯折 180o 时出现将要破裂而未破裂时的温度。 3低温冲击压缩温度即为塑料试样在低温下以一定能量和速度的冲锤对其进行冲击压缩使之破裂率达 50时的温度。 11.耐燃性能耐燃性能是指塑料抵抗火焰燃烧的能力。通常塑料接触火焰后均会燃烧移去火焰后延燃情况随塑料品种不同而不同因此耐燃性能亦有差别。 12.耐热老化性能塑料在加工和使用过程中由于变热导致塑料性能变劣这种现象称为热老化。塑料抵抗热老化的能力称为耐热老化性。采用在高温下进行加速热老化试验测定塑料性能机械性能或电气性能在老化后的保留率来衡量塑料的耐热老化性。 13.耐气候性塑料在大气条件下使用受日晒、雨淋、风吹、大气污染等严酷的自然条件作用塑料性能变劣称为大气老化。塑料抵抗大气老化的能力称塑料的耐气候性。

14.耐油性能及耐溶剂性能塑料与矿物油或各类溶剂接触时抵御油或溶剂的能力称为塑料的耐油性能或耐溶剂性能。可用试样浸入油或溶剂中在一定温度下经一定时间后测定其吸油或溶剂的吸收率、体积变化率或抗拉强度、延伸率的保留率来衡量。 15.耐水性及耐湿性塑料在浸水或潮湿条件下抵御水或潮湿气体渗入的能力称为塑料的耐水性或耐湿性。塑料吸水或吸湿后会引起绝缘电阻、击穿场强下降介质损耗增大且使塑料的外观、重量、机械性能等都有变化。所以要求塑料应具有良好的耐水性和耐湿性。对于电线电缆用塑料主要考虑的是在浸水或吸湿后应保证塑料的电绝缘性能符合使用要求。塑料的吸水量可用单位面积的吸水量、吸水率或吸水重量来表示。塑料的透湿性则以透湿系数和透汽量来表示。

16.耐环境应力开裂性一些结晶型塑料由于加工过程中内应力的存在和使用时接触化学药品致使在贮存和使用中出现开裂称为环境应力开裂。塑料抵御环境应力开裂的能力称为耐环境应力开裂性能。可用表面刻有槽痕的塑料弯曲试样置入表面活性剂中观察在规定时间内出现开裂的试样数量及所占比例来衡量。聚氯乙烯PVC 二、聚氯乙烯PVC 氯乙烯塑料是以聚氯乙烯树脂为基础加入各种配合剂混合而成的。其机械性能优越、耐化学腐蚀、不延燃、耐气候性好、电绝缘性能好、容易加工、成本低因此是电线电缆绝缘和护套用的好材料聚。

1. 聚氯乙烯树脂聚氯乙烯树脂是由氯乙烯聚合而成的线型热塑性高分子化合物聚氯乙烯具有以碳链为主链呈线型含有 C 聚氯乙烯树脂具有下列基本特性 1是热塑性的高分子材料可塑性和柔软性较好。 2由于 C Cl极性键的存在树脂具有较大德极性因此介电常Cl极性键。数 ε 和介质损耗角的正切值较大在低频情况下有较高的耐电强度。另外由于极性键的存在分子间的作用力较大机械强度较高. 3 分子结构中含有氯原子树脂具有不延燃和较好的耐化学腐蚀性及耐气候性。氯原子能破坏分子的晶体结构树脂的耐热性较低耐寒性较差加入适量的配合剂就能改善树脂的性能。 2.聚氯乙烯树脂的种类聚乙烯的聚合方法有悬浮聚合、浮液聚合、本体聚合和溶液聚合四种。聚氯乙烯树脂的制造目前主要采用悬浮聚合方法电线电缆就是采用悬浮法聚氯乙烯树脂。聚氯乙烯悬浮聚合过程中所用树脂的结构形状有疏松型树脂XS 型和紧密型树脂XJ 型。疏松型树脂质地疏松吸油性大易于塑化加工操作控制方便晶点少因此电线电缆用的树脂是疏松型。树脂的特性如下项目粒子直径颗粒外形疏松型树脂50-150μm 不规则由多球并合而成颗粒断面结构疏松多孔微粒间间隙大吸收增塑剂

塑化性能 2. 聚氯乙烯的主要性能 1电绝缘性能聚氯乙烯树脂是一种极性较大的电介质电绝缘性能较好但比较非极性材料如聚乙烯、聚丙烯稍差。树脂的体积电阻率大于 1015 ·cm树脂在 25oC 和 50Hz 频率下的介电常数 ε 为 3.43.6当温度和频率变化时介电常数也随之明显的变化聚氯乙烯的介质损耗正切tgδ为 0.0060.2。树脂的击穿场强不受极性影响在室温和工频条件下的击穿场强比较高。但聚氯乙烯的介质损耗较大因而不适用于高压和高频场合通常用在 1显示字数500 1000 1500 3000 4500阅读区底色茶绿 暗灰 棕褐

范文五:铜导线载流量

矩型截面母线在70℃时的载流量表

尺寸宽x厚(毫米)15X320X325X330X440X440X550X550X660X680X6100X660X880X8100X8120X860X1080X10100X10120X10

25℃1652152653654805406657408701150142510251320162519001155148018202070

单片LMY铝母线载流量(安)交流30℃155202249343451507625695817108018409651240153017851085139017101945

35℃145189233321422475585651765101012559021160143016701015130516001820

25℃1652152653704805456707458801170145510401355169020401180154019102300

直流30℃155202249348451512630700827110013709771274159019201110145018002160

35℃145189233326422479590656774108012809151193148817951040135516802020

25℃21027534047562570086095511251480181013201690208024001475190023102650

单片TMY铜母线载流量(安)交流30℃19825832044758765880889710601390170012401590195522551386178521702490

35℃1852422994185506167578409901350159011601490183021101300167020302330

25℃21027534047562570587096011451510187513451755218026001525199024702950

直流30℃19825832044758766281790210751420176012651650205024401433187023202770

35℃18524229941855062076584510101330165011851545192022901342175021752600

矩型截面母线在70℃时的载流量表

尺寸宽x厚(毫米)60X680X6100X660X880X8100X8120X860X1080X10100X10120X10

2片13501630193516802040239026502010241029603200

3

片17202100250021802620305033802650310036504100

41504650

LMY铝母线载流量(安)

交流(每相)

4片

2片15552055251518402400294533502110273533503900

直流(每相)

3片19402460304023302975362042502720344041604860

565065004片

2片17402110247021602620306034002560310036104100

3片22402720317027903370393043403300399046505200

53005900

TMY铜母线载流量(安)

交流(每相)

4片

2片19902630324524853095381044002725351043255000

直流(每相)

3片24953220394030203850469056003530445053856250

725083504片

注 2.导体扁平放置时,当导体宽度在60毫米及以下时,载流量按表列数值减少5%, 当宽度在60毫米以上时,载流量按表列数值减少8%。

500伏铜芯绝缘导线长期连续负荷允许载流量表

橡皮绝缘导线多根同穿在一根管内时

允许负荷电流(安)25℃

穿金属管

穿塑料管

30℃

穿金属管

穿塑料管

25℃

穿金属管

穿塑料管

塑料绝缘导线多根同穿在一根管内时

允许负荷电流(安)

30℃

穿金属管

穿塑料管

导线截面(mm2)1.01.52.54.06.010.016.02535.050.070.095.0120150185

股

线 芯 结 构单芯直径

成品外径

导线明敷设25℃

30℃

数mmmm1111.177191919498413337

1.131.371.762.242.731.331.681.281.511.811.331.201.082.24

4.44.65.05.56.27.88.8

橡塑橡塑234234234234234234234234皮料皮料根根根根根根根根根根根根根根根根根根根根根根根根2119201815141213121114131112111014131112111013121011109272425202018171716141917161815131917161615131816151514123532333028252325222026232223211926242224211924222122201845424239373330333025353128312824353128312825332926292623585554514943394338344640364036324741374136324438353834308575797068605359524664565055494365575056494461534752464111010510398867769766860807265716456827365726557776861676153

10.614513813512811310090100908010694849484751079585958575100898089807011.818017016815914012211012511098131114103117103921331151051201059312410798112988713.823021521520117515413716014012316314412815013111516514613015013211715413612114012310917.328526526624821519317319517515520118016218216314520518316518516714819217115417315613820.834532032230426023521024021519524122019722420118225022520023020518523421018721519217321.740037537435030027024527825022728025222926023421228526623026524021526624821524822420122

470430440402340310280320290265318291262299271248320295270305280250299276252285262234540490504458385365320360330300358331299336308280380340300355375280355317280331289261

注:1.导电线芯最高允许工作温度+65℃,

2.25毫米及以上铜芯导线导线穿管时应用 “(二)”型结果产品。

BV-105耐热型聚氯乙烯绝缘铜芯电线长期连续负荷载流量表(安)

管径

三根穿管

(毫米)

GDG50℃55℃60℃65℃15151515202525323250505070

15151520252532405050---172534446785113138179213262311362

162332416381107131170203249296345

152230396076102124161192236281327

14212837577296117152181223285308

管径

四根穿管

(毫米)

GDG50℃55℃60℃65℃15151515202532324050505070

15151520253232405050---162331405975101126159193233275320

15212938567196120151184222261305

14202836536791113143174210248289

13192634506386107135164198234272

管径(毫米)GDG

截面(mm2)1.52.54610162535507095120150

明敷二根穿管

50℃55℃60℃65℃50℃55℃60℃65℃2534476089123165205264310380448519

2332445784117157191251295362427494

2236425480111149185238280343405469

2128405175104140174225264324382442

192739517095127160202240292347399

182537487290121152192228278331380

172435466885114144182217264314360

162333436481108136172204240296340

15151520252532325050707070

151520252532405050----

注:1.本电缆的聚氯乙烯绝缘中添加了耐热增塑剂,线芯允许工作温度可达105℃,适用于高温场所,但要求接头

用焊接或绞接后表面锡银处理,电线实际允许工作温度还取决于电线与电线,电线与电器接头的允许工作温度。当接头允许温度为95℃时,表中数据应乘以0.92;接头允许温度为85℃时,表中数据应乘以0.84。2.BLV-105型铝芯耐热线的载流量可按表中数据乘以0.78。

3.本表中载流量数据系经计算得出,仅供使用参考,上海电缆研究所尚未提供试验数据。

塑料绝缘软线、塑料护套线明敷设长期连续负荷允许载流量表

截面(毫米2)

2.5

BLVV铝芯

4.06.0100.120.2

RVRVVRVBRVSRFBRFSBVVGBVVJBVV铜芯

0.30.40.50.751.01.52.02.54.06.010

25℃253443595791112.51619242832425575

233140554.56.581011.514.517222629395170

13.510212427364764单芯30℃

35℃21293751467.59.5

40℃192634463.55.578.59.512.515182225334359

25℃2026335145.578.59.512.515192226364765

182430473.556.57.58.511.514172024334360二芯30℃

35℃1722284434.567810.512161922314056

40℃15202640345.56.57.59.511151720283751

25℃1622254034567911141720263252

142023372.53.54.55.56.5810131518242948三芯30℃

35℃131921342.534567.59121417222744

40℃12171931233.54.55.578111315202541

注:1.导线芯最高允许工作温度为65℃。

单相电压220V时功率因数

功率P(KW)0.500.751.001.251.501.752.002.252.502.753.003.253.503.754.004.254.504.755.00

0.58

3.925.887.849.80

0.603.795.687.589.47

0.623.675.507.339.16

0.643.555.337.108.88

0.663.445.176.898.61

0.683.345.016.688.36

0.703.254.876.498.129.74

0.723.164.736.317.899.47

0.743.074.616.147.689.21

0.762.994.495.987.488.97

0.782.914.375.837.288.74

0.802.844.265.687.108.529.94

0.822.774.165.546.938.319.70

0.842.714.065.416.768.129.47

0.862.643.965.296.617.939.25

0.882.583.875.176.467.759.04

0.902.533.795.056.317.588.84

0.922.473.714.946.187.418.659.88

0.942.423.634.846.047.258.469.67

0.962.373.554.735.927.108.299.47

0.982.323.484.645.806.968.129.28

1.002.273.414.555.686.827.959.09

I(安)

11.7611.3611.0010.6510.3310.03

13.7113.2612.8312.4312.0511.7011.3611.0510.7510.4710.20

15.6715.1514.6614.2013.7713.3712.9912.6312.2911.9611.6611.3611.0910.8210.5710.3310.10

17.6317.0516.5015.9815.5015.0414.6114.2013.8213.4613.1112.7812.4712.1811.8911.6211.3611.1210.8810.6510.4410.2319.5918.9418.3317.7617.2216.7116.2315.7815.3614.9514.5714.2013.8613.5313.2112.9112.6312.3512.0911.8411.6011.3621.5520.8320.1619.5318.9418.3817.8617.3616.8916.4516.0315.6315.2414.8814.5314.2013.8913.5913.3013.0212.7612.5023.5122.7321.9921.3120.6620.0519.4818.9418.4317.9417.4817.0516.6316.2315.8615.5015.1514.8214.5114.2013.9113.6425.4724.6223.8323.0822.3821.7221.1020.5219.9619.4418.9418.4718.0217.5917.1816.7916.4116.0615.7215.3915.0714.7727.4326.5225.6624.8624.1023.4022.7322.1021.5020.9320.4019.8919.4018.9418.5018.0817.6817.2916.9216.5716.2315.9129.3928.4127.4926.6325.8325.0724.3523.6723.0322.4321.8521.3120.7920.2919.8219.3718.9418.5318.1317.7617.3917.0531.3530.3029.3328.4127.5526.7425.9725.2524.5723.9223.3122.7322.1721.6521.1420.6620.2019.7619.3418.9418.5518.1833.3132.2031.1630.1829.2728.4127.6026.8326.1125.4224.7724.1523.5623.0022.4621.9521.4621.0020.5520.1219.7119.3235.2734.0932.9931.9630.9930.0829.2228.4127.6426.9126.2225.5724.9424.3523.7823.2422.7322.2321.7621.3120.8720.4537.2335.9834.8233.7432.7131.7530.8429.9929.1828.4127.6826.9926.3325.7025.1124.5423.9923.4722.9722.4922.0321.5939.1837.8836.6635.5134.4433.4232.4731.5730.7129.9029.1428.4127.7227.0626.4325.8325.2524.7024.1823.6723.1922.73

单相电压220V时功率因数

功率P(KW)5.255.505.756.006.256.506.757.007.257.507.758.008.258.508.759.009.259.509.7510.00

0.580.600.620.640.660.680.700.720.740.760.780.800.820.840.860.880.900.920.940.960.981.00

I(安)

41.1439.7738.4937.2936.1635.0934.0933.1432.2531.4030.5929.8329.1028.4127.7527.1226.5225.9425.3924.8624.3523.8643.1041.6740.3239.0637.8836.7635.7134.7233.7832.8932.0531.2530.4929.7629.0728.4127.7827.1726.6026.0425.5125.0045.0643.5642.1640.8439.6038.4437.3436.3035.3234.3933.5132.6731.8731.1130.3929.7029.0428.4127.8027.2326.6726.1447.0245.4543.9942.6141.3240.1138.9637.8836.8635.8934.9734.0933.2632.4731.7130.9930.3029.6429.0128.4127.8327.2748.9847.3545.8244.3943.0441.7840.5839.4638.3937.3836.4235.5134.6533.8233.0332.2831.5730.8830.2229.5928.9928.4150.9449.2447.6546.1644.7743.4542.2141.0439.9338.8837.8836.9336.0335.1734.3633.5732.8332.1131.4330.7830.1529.5552.9051.1449.4947.9446.4945.1243.8342.6141.4640.3739.3438.3537.4236.5335.6834.8734.0933.3532.6431.9631.3130.6854.8653.0351.3249.7248.2146.7945.4544.1943.0041.8740.7939.7738.8037.8837.0036.1635.3534.5833.8533.1432.4731.8256.8254.9253.1551.4949.9348.4647.0845.7744.5343.3642.2541.1940.1939.2338.3237.4536.6235.8235.0634.3333.6332.9558.7856.8254.9953.2751.6550.1348.7047.3546.0744.8643.7142.6141.5740.5839.6438.7437.8837.0636.2735.5134.7934.0960.7458.7156.8255.0453.3751.8050.3248.9347.6046.3545.1644.0342.9641.9440.9640.0339.1438.2937.4836.7035.9535.2362.7060.6158.6556.8255.1053.4851.9550.5149.1447.8546.6245.4544.3543.2942.2841.3240.4039.5338.6837.8837.1136.3664.6662.5060.4858.5956.8255.1553.5752.0850.6849.3448.0846.8845.7344.6443.6042.6141.6740.7639.8939.0638.2737.5066.6164.3962.3260.3758.5456.8255.1953.6652.2150.8449.5348.3047.1246.0044.9343.9042.9342.0041.1040.2539.4238.6468.5766.2964.1562.1460.2658.4956.8255.2453.7552.3350.9949.7248.5047.3546.2545.2044.1943.2342.3141.4340.5839.7770.5368.1865.9863.9261.9860.1658.4456.8255.2853.8352.4551.1449.8948.7047.5746.4945.4544.4743.5242.6141.7440.9172.4970.0867.8265.7063.7161.8360.0658.4056.8255.3253.9052.5651.2750.0548.8947.7846.7245.7044.7343.8042.9042.0574.4571.9769.6567.4765.4363.5061.6959.9758.3556.8255.3653.9852.6651.4150.2149.0747.9846.9445.9444.9844.0643.1876.4173.8671.4869.2567.1565.1763.3161.5559.8958.3156.8255.4054.0552.7651.5350.3649.2448.1747.1546.1645.2244.3278.3775.7673.3171.0268.8766.8464.9463.1361.4359.8158.2856.8255.4354.1152.8551.6550.5149.4148.3647.3546.3845.45

三相四线,电压380V时功率因数

功率P(KW)0.500.751.001.251.501.752.002.252.502.753.003.253.503.754.004.254.504.755.00

0.58

1.311.962.613.273.924.575.225.886.537.187.848.499.149.80

0.601.261.892.533.163.794.425.055.686.316.947.588.218.849.47

0.621.221.832.443.053.674.284.895.506.116.727.337.948.559.169.78

0.641.181.782.372.963.554.144.735.335.926.517.107.698.298.889.47

0.661.151.722.302.873.444.024.595.175.746.316.897.468.038.619.189.76

0.681.111.672.232.793.343.904.465.015.576.136.687.247.808.368.919.47

0.701.081.622.162.713.253.794.334.875.415.956.497.037.588.128.669.209.74

0.721.051.582.102.633.163.684.214.735.265.796.316.847.377.898.428.949.47

0.741.021.542.052.563.073.584.104.615.125.636.146.657.177.688.198.709.219.73

0.761.001.501.992.492.993.493.994.494.985.485.986.486.987.487.978.478.979.479.97

0.780.971.461.942.432.913.403.894.374.865.345.836.316.807.287.778.268.749.239.71

0.800.951.421.892.372.843.313.794.264.735.215.686.166.637.107.588.058.529.009.47

0.820.921.391.852.312.773.233.704.164.625.085.546.016.476.937.397.858.318.789.24

0.840.901.351.802.252.713.163.614.064.514.965.415.866.316.767.227.678.128.579.02

0.860.881.321.762.202.643.083.523.964.404.845.295.736.176.617.057.497.938.378.81

0.880.861.291.722.152.583.013.443.874.304.735.175.606.036.466.897.327.758.188.61

0.900.841.261.682.102.532.953.373.794.214.635.055.475.896.316.737.157.588.008.42

0.920.821.241.652.062.472.883.293.714.124.534.945.355.766.186.597.007.417.828.23

0.940.811.211.612.012.422.823.223.634.034.434.845.245.646.046.456.857.257.668.06

0.960.791.181.581.972.372.763.163.553.954.344.735.135.525.926.316.717.107.507.89

0.980.771.161.551.932.322.713.093.483.874.254.645.025.415.806.186.576.967.347.73

1.000.761.141.521.892.272.653.033.413.794.174.554.925.305.686.066.446.827.207.58

I(安)

10.4510.10

11.1010.7310.3910.06

11.7611.3611.0010.6510.3310.03

12.4111.9911.6111.2510.9010.5810.2810.00

13.0612.6312.2211.8411.4811.1410.8210.5210.24

三相四线,电压380V时功率因数

功率P(KW)5.255.505.756.006.256.506.757.007.257.507.758.008.258.508.759.009.259.509.7510.00

0.580.600.620.640.660.680.700.720.740.760.780.809.94

0.829.70

0.849.479.92

0.869.259.69

0.889.049.479.90

0.908.849.269.68

0.928.659.069.479.88

0.948.468.879.279.67

0.968.298.689.089.479.86

0.988.128.508.899.289.66

1.007.958.338.719.099.479.85

I(安)

13.7113.2612.8312.4312.0511.7011.3611.0510.7510.4710.20

14.3713.8913.4413.0212.6312.2511.9011.5711.2610.9610.6810.4210.16

15.0214.5214.0513.6113.2012.8112.4512.1011.7711.4611.1710.8910.6210.3710.13

15.6715.1514.6614.2013.7713.3712.9912.6312.2911.9611.6611.3611.0910.8210.5710.3310.10

16.3315.7815.2714.8014.3513.9313.5313.1512.8012.4612.1411.8411.5511.2711.0110.7610.5210.2910.07

16.9816.4115.8815.3914.9214.4814.0713.6813.3112.9612.6312.3112.0111.7211.4511.1910.9410.7010.4810.2610.05

17.6317.0516.5015.9815.5015.0414.6114.2013.8213.4613.1112.7812.4712.1811.8911.6211.3611.1210.8810.6510.4410.2318.2917.6817.1116.5716.0715.6015.1514.7314.3313.9613.6013.2612.9312.6312.3312.0511.7811.5311.2811.0510.8210.6118.9418.3117.7217.1616.6416.1515.6915.2614.8414.4514.0813.7313.4013.0812.7712.4812.2111.9411.6911.4411.2110.9819.5918.9418.3317.7617.2216.7116.2315.7815.3614.9514.5714.2013.8613.5313.2112.9112.6312.3512.0911.8411.6011.3620.2519.5718.9418.3517.7917.2716.7716.3115.8715.4515.0514.6814.3213.9813.6513.3413.0512.7612.4912.2311.9811.7420.9020.2019.5518.9418.3717.8317.3216.8416.3815.9515.5415.1514.7814.4314.0913.7713.4713.1812.8912.6312.3712.1221.5520.8320.1619.5318.9418.3817.8617.3616.8916.4516.0315.6315.2414.8814.5314.2013.8913.5913.3013.0212.7612.5022.2021.4620.7720.1219.5118.9418.4017.8917.4016.9516.5116.1015.7115.3314.9814.6314.3114.0013.7013.4213.1412.8822.8622.1021.3820.7120.0919.5018.9418.4117.9217.4417.0016.5716.1715.7815.4215.0714.7314.4114.1013.8113.5313.2623.5122.7321.9921.3120.6620.0519.4818.9418.4317.9417.4817.0516.6316.2315.8615.5015.1514.8214.5114.2013.9113.6424.1623.3622.6121.9021.2420.6120.0219.4718.9418.4417.9717.5217.0916.6816.3015.9315.5715.2314.9114.6014.3014.0224.8223.9923.2222.4921.8121.1720.5619.9919.4518.9418.4517.9917.5517.1416.7416.3615.9915.6515.3114.9914.6914.3925.4724.6223.8323.0822.3821.7221.1020.5219.9619.4418.9418.4718.0217.5917.1816.7916.4116.0615.7215.3915.0714.7726.1225.2524.4423.6722.9622.2821.6521.0420.4819.9419.4318.9418.4818.0417.6217.2216.8416.4716.1215.7815.4615.15

宇智波

宇智波