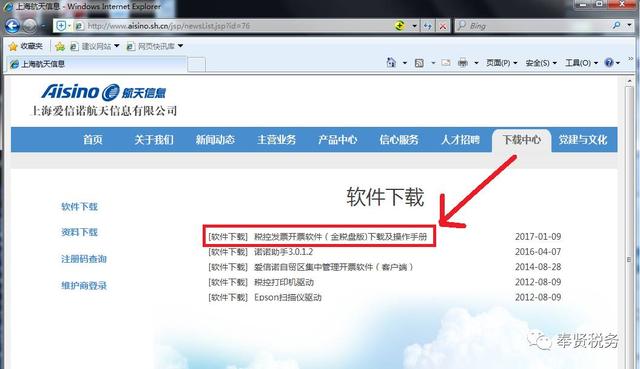

范文一:税控发票开票软件(金税盘版)升级培训

税控发票开票软件(金税盘版)升级培训

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

to comply with the requirements. (6) pressure pipes are installed according to the design requirements of the system pressure test, segmented tiered when pressure testing to be carried out in sequence, drainage, stormwater pipes to do water testing, and recording, pressure test failed or untested pipeline may not be concealed. Test pressure is the pressure piping installation one stops. (7) the control interface of pipeline leakage from the processing begins. Thread processing to tight fit, length should comply with the requirements. Flange after welding to check end verticality, checking the welding quality. (8) electrical engineering should control the grounding line of weld quality and laying of pipeline quality, timely measurement of grounding resistance, and completes the record. (9) the phase and neutral and ground wire to strictly control the installation location may not be wrong, to multi color lines as required. (10) the distribution box, distribution bottle Shell to a separate ground line, shell transitions can not be used. (C) the pipeline installation engineering 1. construction sequence (1) be familiar with design drawings and related technical information; (2) construction survey and setting out; (3) cooperate with the reserved, embedded civil work; (4) pipe and tube processing (5) support (hanging) production; (6) the pipe prefabrication and Assembly; (7) the pipe laying and installation; (8) the pipes connected to the device; (9), instrumentation and piping installed; (10) pressure test and cleaning (blowing) washing; (11), anti-corrosion and thermal insulation; (12) acceptance. 2. construction conditions (1) the design drawings, specifications and other technical documentation is complete, and after a trial. (2) construction project

范文二:北京航天金税客服中心开票软件(金税盘版)常见问题(二)

1

金税盘登陆密码和口令是多少?

答:情况1:营改增企业领取金税盘后初次安装,或其他原因到税局重新发行、重签证书,默认的登陆密码是123456 ? 证书口令是88888888

情况2 :很多用户因为电脑硬件问题或其他原因需要重新安装开票系统,重装后登陆时的密码和证书口令一时记不清。密码是123456 ?证书口令是23456789

注:初次安装在航天金税工程师帮您安装时或培训后老师会告知您,口令已经由原始的88888888改为23456789

2

如何添加客户编码?

答:系统设置-客户编码-将带有*号的内容填写正确后保存

3

如何添加商品编码?

答:系统设置-商品编码-将带有*号的内容填写正确后保存

4税收分类编码如何选择?

答:2016年3月2日前购买的金税盘开票前需要添加商品编码,设置方法如下:

以餐费为例:点击系统设置-商品编码-将带有*号的内容进行填写和选择。注意:生活服务业税率的规定是:一般纳税人提供生活服务适用税率为6%,一小规模纳税人提供生活服务适用税率为3%,实际情况请以税务机关规定为准。

点击税收分类编码上的小图标进行编码选择

开具餐费需要到销售服务-生活服务-餐饮住宿服务里选择餐饮服务

设置完成点击保存

进入发票填开界面-输入正确信息、选择正确税率确认无误后可点击打印。

【温馨提示】用正式发票打印前需要调整好位置,避免造成损失!

5

开票软件已经是最新版本却没有更新税收分类编码如何操作?

答:如果版本没有问题编码内容没有更新,需要在电脑联网状态下点击系统设置-编码管理-商品和服务税收分类编码界面-点【更新】-退出系统改重新登陆。

6

如何开具增值税普通发票?

答:发票管理-发票填开-增值税普通发票填开。进入发票填开界面,先确定您开具的发票含税状态,按“价格”可进行切换,信息确认无误后方可打印。

7

如何开具增值税专用发票?

答:发票管理-发票填开-增值税专用发票填开-出现票号确认。

进入发票填开界面,先确定您开具的发票含税状态,按“价格”可进行切换,购买方信息、金额等信息确认无误后打印发票。

8

离线发票累计限额超限怎么处理?

答:方法1:先确定您的电脑网络和时间是正常状态,点击系统设置-参数设置-上传设置-安全接入服务器地址设置成https://tysl.bjtax.gov.cn测试成功后,点击发票管理-发票修复-退出系统重新登陆,查看发票查询中所有发票报送状态为已报送时则正常开票。

方法2:在网络环境和服务器地址测试正常时,点击发票管理-发票查询-发票上传所有发票报送状态为已报送时则正常开票

9

发票信息输入后如何调整发票打印位置?

答:您可以从发票查询中找到之前开过的发票,用A4纸进行调试,在边距调整内输入数值进行调整。初次打印可先在打印机内放置复印好的发票样票或发票复印件。放入后即可点击“打印”按钮。因打印机型号不同,边距调整中的数值需自行调整。

调整规律是:

向下调整:数值越大,发票内容越向下,数值越小,发票内容越向上

向右调整:数值越大,发票内容越向右,数值越小,发票内容越向左

注:“向下调整”和“向右调整”格内可以填写正负数值,数值以毫米为单位

10增值税专票开错了如何处理?

答:当月开错的发票,未经抄报,可以直接作废:发票管理-发票作废-选中需要作废的发票-点作废

跨月开错的专票:

1.发票管理——信息表——红字增值税专用发票信息表填开-填写信息后打印

2.进入红字增值税专用发票信息表查询导出界面选中开具的红字发票信息表点击上传

3.上传成功后生成信息表编号

4.进入专用发票填开界面点击“红字”,选择“直接开具”,将信息表编号直接输入后点“确定”,核实信息无误后方可打印。

注:请您按照实际情况填写,避免上传错误

11

增值税普票开错了如何处理?

答:当月开错的发票,未经抄报,可以直接作废:发票管理-发票作废-选中需要作废的发票-点作废

跨月开错的普票,进入发票填开界面点击“红字”——输入发票号码、发票代码后核实信息无误后打印。

注:请您按照实际情况填写,避免上传错误

12

误将正确的发票作废,是否可以恢复正常状态?

答:不可以,已经作废的发票无法恢复正常状态

13由于电脑硬件原因或办公地址变更等原因导致开票软件重新安装,上月的开票数据如何恢复?

答:发票管理-发票修复-选择月份

14

小规模和一般纳税人征期抄报方法分别是什么

答:(1)一般纳税人抄报方法

进入系统进行自动上报汇总——进行纳税申报——进入系统完成自动清卡

小规模纳税人抄报方法:

(2)一般纳税人抄报方法

1.小规模季报月份为1月、4月、7月、10月这四个月份抄报税时需要进行票表比对,有先后顺序,与一般纳税人的抄报方法一致。

2.非季报月份无需比对直接进入系统完成自动抄报和清卡(进入系统时会提示清卡成功)

15

如何查询是当月已经清卡

答:以5月征期为例:查询5月是否清卡成功您可以按照以下方法查询:

报税处理-状态查询-增值税专用发票及增值税普通发票

抄税起始日期:2016.06.01

上次报税日期:2016.05.01

报税资料:无

这样的状态说明5月已经完成清卡工作。

16

该版本不支持非征期抄报?

点击报税处理——状态查询——增值税专用发票和普通发票

当抄税起始日期为下月1日,且报税资料为无时,说明您已经完成清卡,无须报税等操作。

若您抄税起始日期为下月1日,且报税资料为有时,说明您已经抄税成功,请做纳税申报,申报成功后进入系统清卡即可。

若您抄税起始日期为本月1日,且报税资料为有时,请你携带相关资料去办税大厅进行清卡。清卡后回来正常抄报税即可。

17存在离线发票不能上报汇总?

1.保持电脑网络和系统时间是正常状态。

2.系统设置—参数设置—上传设置—上传服务器地址?https://tysl.bjtax.gov.cn??点击测试,提示成功后。请点击“发票管理”—“发票修复”,并选择全年,提示发票修复成功后,等待发票查询中所有发票报送状态显示已报送再做上报汇总。

18

SSL通道安全连接不成功

1.检查网络连通,电脑系统时间正确。 2.在系统设置—系统参数设置—基本参数设置—上传设置-安全接入服务器地址https://tysl.bjtax.gov.cn测试连接成功。 3.核对操作系统日期为正确日期。4.退出系统重新登陆后再试。

19

如何打印明细表、汇总表?

答:报税处理-发票资料-选择年份、月份、所属税期票种等信息后点击查询

20

如何添加收款人、复核人?

点击系统维护-角色管理-添加收款人、复核人角色;在进入系统维护-用户管理-添加收款人和复核人的姓名,开票时就可以直接选择添加好的姓名。

范文三:【问题典籍】北京航天金税客服中心开票软件(金税盘版)常见问题

2017-02-13 航天金税

1.五证合一后开票软件登录(1)您从国税大厅变更税号后无需重装直接登录,税号信息如果已经更新,可以正常使用。

(2)如果登录时出现错误提示,需要重新安装开票软件,登录密码是123456,证书口令88888888,登录后会提示您需要修改证书口令,建议您改为23456789方便记忆。

注意:

*因电脑原因导致的开票软件重装,金税盘登录密码是123456,证书口令23456789(修改后的口令)

*共5次输错口令机会,连续输错5次会导致金税盘口令锁死,需要到国税大厅重签证书。

2.抄报税方法一般纳税人每月征期抄报方法和小规模季报方法如下图

查询清卡是否成功方法:

点击报税处理——状态查询——增值税专用发票和普通发票

当抄税起始日期为下月1日,且报税资料为无,说明您已经完成清卡。

3.V2.1版本金税盘的服务器地址设置

安装过程中需要核实此地址是否正确,可能会影响您抄报税

注意:

如果您输入的服务器地址没有问题,上报汇总还提示SSL网关问题,建议您退出开票系统,调整电脑时钟为北京时间,并切换英文输入法重新输入服务器地址进行测试。

4.登录时提示密钥容器不存在您可以登录航天金税网站-下载中心-下载开票软件安装程序, 进行升级安装。或联系小蜜蜂给您发送解决方法

5.开票软件编码开票方法进入发票填开界面也可以直接选择,点击货物或应税劳务服务,添加商品名称。例如开具“打印机”,双击打印机或描述中含有打印机的项目,将带*号的项目正确填好保存。

税收分类编码需要点击框内小图标进行选择;税收优惠的企业在享受优惠政策位置选择是并选择优惠政策类型。

6.点击上报汇总提示“抄报数据上传失败”

请您检查“系统设置-参数设置-上传设置”

安全接入服务器地址: https://tysl.bjtax.gov.cn

测试成功后点击确定,再点击上报汇总进行抄税。

7.离线发票累计限额超限怎么处理?

方法1:先确定您的电脑网络和时间是正常状态,点击系统设置-参数设置-上传设置-安全接入服务器地址设置成https://tysl.bjtax.gov.cn测试成功后,点击发票管理-发票修复-退出系统重新登陆,查看发票查询中所有发票报送状态为已报送时则正常开票。

方法2:在网络环境和服务器地址测试正常时,点击发票管理-发票查询-发票上传所有发票报送状态为已报送时则正常开票

8.该版本不支持非征期抄报?

点击报税处理——状态查询——增值税专用发票和普通发票

当抄税起始日期为下月1日,且报税资料为无,说明您已经完成清卡,无须报税等操作。

若您抄税起始日期为下月1日,且报税资料为有,说明您已经抄税成功,请做纳税申报,申报成功后进入系统清卡即可。

若您抄税起始日期为本月1日,且报税资料为有,请你携带相关资料去办税大厅进行清卡。清卡后回来正常抄报税即可。

9.开票软件重新安装之前的数据如何恢复发票管理-发票修复-全年度数据

10.当月开错的发票如何作废?发票管理-发票作废-选中需要作废的发票-点击作废按钮

11.跨月的专票和普票如何处理专票跨月的处理方法

1.发票管理——信息表——红字增值税专用发票信息表填开-填写信息后打印

2.进入红字增值税专用发票信息表查询导出界面选中开具的红字发票信息表点击上传

3.上传成功后生成信息表编号

4.进入专用发票填开界面点击“红字”,选择“直接开具”,将信息表编号直接输入后点“确定”,核实信息无误后方可打印。

注:请您按照实际情况填写,避免上传错误

普票跨月的处理方法

进入发票填开-红字-按照提示输入发票号码、发票代码,核实信息无误后用正式发票打印。

12.如何打印明细、汇总答:报税处理-发票资料-选择年份、月份、所属税期票种等信息后点击查询

13.不请卡可以开票吗?可以,征期内抄税成功就可以开票。

14.上报汇总提示 不允许注销报税?

答:该问题是因为您的开票系统跨月没有清卡导致,建议您携带金税设备,公章,税务登记证副本及明细汇总表去办税厅大厅窗口手工清卡,具体携带材料请以所属税务机关要求为准。

15.纳税申报后不能清卡请您检查开票软件是否已经完成清卡,如果退出系统重新登录几次都没有效果可以到国税办税大厅清卡。

16.开票软件版本更新方法

请您登陆航天金税网站-下载中心-税控发票开票软件(可用于变更三证合一税号 金税盘版)V2.1.20.161225,下载地址和方法http://64155500.com/download.php?id=1570

将金税盘插好,再运行安装程序,税号、开票机号、地区编号会自动显示,直接进行下一步

注意:进行版本升级需要选择升级安装,初次在电脑安装选择完全安装,其他都是下一步。

17.发票明细数据可以导出吗?报税处理-报税管理-发票数据导出-选择时间段进行查询、打印

18.进入开票软件时出现未响应的情况您需要从航天金税网站-下载中心,下载安装程序进行完全安装。模板最新版本号是V2.1.20.161225

(下载地址:http://64155500.com/download.php?id=1570)

注意:完全安装后您将无法查询到之前设置过的商品编码和客户编码,以及之前开具的明细数据。

19.如何设置收款人、复核人点击系统维护-角色管理-添加收款人、复核人角色;在进入系统维护-用户管理-添加收款人和复核人的姓名,开票时就可以直接选择添加好的姓名。

20.如何调整发票打印位置方法一:系统设置-系统设置-打印位置设置

方法二:从发票查询找到开过的发票,选中点击打印

两种方法的调试规律都是一样的,

向下:数值越大,发票内容越向下,数值越小,发票内容越向上

向右:数值越大,发票内容越向右,数值越小,发票内容越向左

注:“向下调整”和“向右调整”格内可以填写正负数值,数值以毫米为单位

范文四:金税盘版 ▌北京航天金税客服中心开票软件常见问题

2016-06-22 北京国税

导语使用金税盘版开票软件的纳税人,是不是经常遇到一些问题呢?别急,小编今天特意对这些问题进行了整理,分期送给大家,以期纳税人朋友顺利掌握并成功开票!来,看看今天这十个常见问题吧!

01问:网络购入的发票(票e送)如何读入?

答:待收到邮寄的纸质发票后,进入开票软件:发票管理→发票领用管理→网上领票。

在网上领票界面中,在选择了购票日期时间段(默认为当月)后,点击“查询”按钮,会出现之前在网上领票系统申请的电子发票,仔细核对发票种类、发票代码、发票起始号码和发票份数等信息,确认无误后点击“发票下载”按钮。

金税盘开票软件除了提供查询下载的功能外,还提供了网上领票“手工下载”的功能,如下图,手工选择并输入收到的纸质发票类型、发票代码、发票起始号码和发票张数等信息后,点击“下载”按钮。

如果出现下图所示界面,则表明发票下载成功。

注意:在完成网上领票后,不需要再执行“发票读入”操作,可直接点击“发票填开”开具发票。

02问:开票软件中无法开具1.5%或5%税率的发票?

答:您需要从航天金税网站-下载中心,下载V2.1.20.160425.01版本的安装程序进行升级安装。

(下载地址:http://64155500.com/download.php?id=1570)

03问:企业进行工商、税务变更三证合一后,开票软件如何自动变更税号?

答:您需要从航天金税网站-下载中心,下载V2.1.20.160425.01版本的安装程序进行升级安装。

(下载地址:http://64155500.com/download.php?id=1570)

04问:开票是不能输入金额,或其他内容?

答:这种问题一般都是输入法导致的,可切换成半角或英文状态,或退出开票界面重新进入。

05问:由于其他原因需要作废开票软件中剩余的空白发票,如何操作?

答:发票管理-发票管理-未开发票作废。

06问:因打印机设置等原因导致发票在系统中已经生成却未打印,可以重复打印吗,有次数限制吗?

答:可以重复打印,没有次数限制。

注意:打印前需确定打印位置,避免不必要的损失。

07问:红字发票信息表开错了如何处理?

答:红字发票信息表上传有两种情况:

(1)未上传或未上传成功

处理方法:可直接在开票系统中作废,无需到大厅处理;

(2)已经上传、审核通过

应凭纸质的《开具红字增值税专用发票信息表》(加盖公章)、情况说明(加盖公章)及经办人身份证原件到办税服务厅办理撤销。

08问:开票软件是否可以开外币的发票?

答:不可以。

09问:已经清卡,不小心点了办税厅抄报,如何处理?

答:因新版开票软件不支持非征期清卡,请您携带金税设备,公章,税务登记证副本以及明细汇总表,前往您主管税务所进行清卡操作。

10问:2.0 上报汇总提示 不允许注销报税?

答:该问题是因为您的开票系统跨月没有清卡导致,建议您携带金税设备,公章,税务登记证副本及明细汇总表去办税厅大厅窗口手工清卡,具体携带材料请以所属税务机关要求为准。

来源:航天金税

范文五:【操作指南】航天版开票软件升级操作指南

01查看系统版本号

A、使用易用系统的用户

双击计算机桌面“航信易用系统”图标,具体版本号查看如下图:

B、使用防伪税控系统的用户

双击计算机桌面“防伪开票”图标,具体版本号查看如下图:

02低于V2.1.30.161225版本

升级下载地址

请打开浏览器,在地址栏输入“www.gx95113.com”访问,点击“下载中心”选择“广西航信易用开票系统(附增值税开票软件V.2.1.30.161225版)”

03软件重装

数据备份

一、数据备份

情况一:系统无法登陆:

第一步:进入系统根目录(默认路径:C:\\Program Files\\开票软件)

找到“开票软件”文件夹拷贝。(为便于查找建议暂时粘贴至电脑桌面)

情况二:可以正常登陆系统:

第一步:客户编码导出:点击“系统设置/客户编码”选择导出。

商品编码导出:[系统设置]—[客户编码],导出。

04软件重装

软件安装

接入金税盘

情况一:软件安装过程中核对好税号等信息直接点击“下一步”进行即可,到达“选择组件”界面注意选择为“升级安装”即可。

05软件重装

数据恢复

注意:选择“升级安装”数据不会丢失,若进入系统数据还存在,请勿执行该步骤操作。

情况一:

之前备份的开票软件/税号.0/Bin的名为cc3268.dlll文件覆盖回以下路径C:Program Files/开票软件税号.0/Bin中替换,如下图所示

情况二:

第一步:恢复客户编码:客户编码导入:点击“系统设置/设置编码”导入

第二步:恢复商品编码:商品编码导入:点击“系统设置/客户编码”,点击“导入”按钮。

转载请注明出处范文大全网 » 税控发票开票软件金税盘版升级

段友大集合

段友大集合